There is no secret to finding the next big thing, the industry disrupter, or the million-dollar idea that people wish they had thought of first. The truth is, innovation begins with listening.

There are opportunities all around us, waiting for someone to beg the question, what would make your job easier? The best ideas solve the most common problems, and you can’t find solutions if you’re not asking questions. It’s a simple, but effective approach, and it’s the way PRIER initiates the first phase of product development.

During a conversation with a plumbing engineer, Regional Sales Manager, Angelo Balistreri, asked the question – what can we do to make your job easier? She had an answer queued up quickly and with an open ear, he listened to a story about a job she had worked on that began with a hydrant installation and ended with a basement full of water.

The Problem: Water intrusion from the outside of a commercial hydrant back into the building in which it was installed.

“A metal-on-metal installation of a commercial hydrant into a hydrant box leaves a very slight, unseen gap that can allow for water to find its way in,” says Scott Brady, R&D Manager at PRIER.

Turns out, the commercial hydrant in the story, as told by the engineer, was installed correctly, but used improperly. A maintenance worker hooked up a power washer to the hydrant without fully securing the connection and spray-back from the hose flowed over the hydrant inside the box for several hours. Luckily the water was found the next day, removed from the basement, and considerable property damage was avoided.

It begged several questions, though. How could we improve the overall experience with a commercial hydrant? What would make the installation easier, the engineer’s job less stressful, and the user’s experience more effective?

The Solution: Create a seal that prevents water intrusion into the interior wall.

Wow, that seems easy. Hasn’t someone done that already? Actually, no.

In the plumbing industry, innovation can move slowly. Tool technology has come a long way and so has technique, but for the most part, real operational changes over the last 50 years have been scarce.

So while the idea of sealing a valve off to prevent water leakage is not a new problem, the solution so far has been to caulk around the hydrant’s edge on the inside of the box, leaving room for error and eventual deterioration of the sealant. Unless there’s a seasoned and thorough plumber at the helm of every installation, there will be inherent water damage risk.

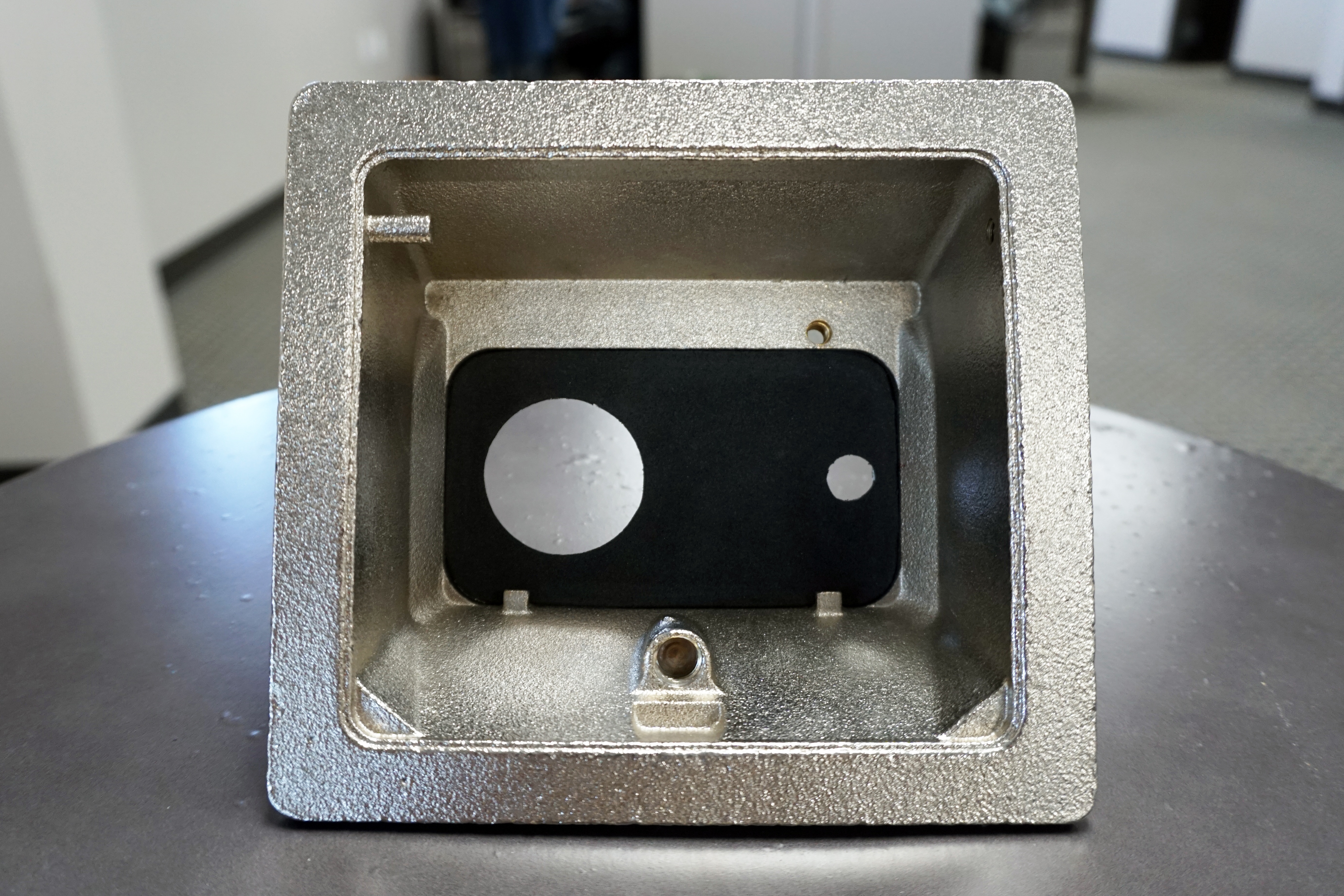

PRIER's Answer: The C-634 Gasket

Funding decisions are based by a philanthropic vision based in the belief people’s lives are enriched through caring connections.

Some of our favorite organizations include:

Made of a basic foam, die-cut into a simple shape mirroring the interior of the C-634 hydrant box, the gasket seals the gap between two metal surfaces, preventing water damage and future headaches. The innovation isn’t rocket science, but it is thoughtful.

Most gaskets are secured by at least four perimeter screws with the balance of symmetry ensuring a seal. Due to the architecture of the valve within the box, there are only three locations to compress a seal – the two feet in the corners of the bottom interior edge, and one truss in the top right interior. Our engineering team was faced with the challenge of finding the right material that would compress enough to hold the seal, but still maintain some pliability for an easy installation.

Thorough testing of many prototypes, and then even more testing of the chosen design brought us to the final version that solves the problem at hand.

Moving Forward

PRIER believes that every product we send to customers should be our best effort, A-quality work, and the last thing a property owner should have to worry about on their long list of building improvements. For this same reason, we are including a C-634 gasket with the purchase of every C-634 hydrant box. There’s no additional line item or special order required – it’s just a part of the installation process and it gives the customer the best chance at success with our product.

In the age of add-ons and upgrades, perhaps even this simple inclusion is where some innovation lies. However, for us, it’s not about coming up with a new product trend or knowing we are the only plumbing manufacturer creating commercial hydrant gaskets – it is the intuitive, simple answer to an age-old problem that our industry faces. It’s why we continue to ask the important questions, and then listen to the plumbers, engineers, and business owners when they answer.